Description

Electrolyser research and development provides the crucial link to make the renewable energy concept and hydrogen energy a reality. The unpredictability of having the supply of power when needed will no more be an issue. Excess unused power generated from solar and wind can be used to generate, and store hydrogen for a later use for filling a car, and/or to use in a fuel cell for distributed, emergency power and other hydrogen energy solutions.

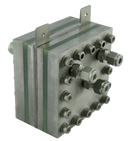

The Electrolyser Test Cell Hardware provides a reliable hardware with many built-in flexibilities for studying different materials for flow-field, different catalysts, membranes, and current distributors.

Water electrolysis takes place in an electrolyser using electricity to split water. At the anode electrode, water is split to form oxygen and protons. At the cathode electrode, the supplied electricity combines with protons to form hydrogen. The protons transport from anode to cathode through a proton exchange membrane to complete the electrolyzer reaction. High electrically conductive and corrosion resistant materials are required to support high performance and long endurance testing.

Key Features:

- Design for quick assembly and re-assembly – easy drop-in installation guided by alignment pins and flat gaskets

- Built with titanium – giving high electrical conductivity and corrosion resistance, comprising current collectors, separator plates and flow field internal parts

- Basic square design – high material utilization in square vs circular and easy fabrication

- Built-in thermal couple for close temperature measurement and control at the center of the cell

Specifications:

- Active Area: 5cm² or 50cm²

- Cell body dimension (H x W x T): 10.1 cm x 10.1 cm x 1.0 cm (50cm²)

- Overall body dimension (H x W x T): 15.4 cm x 13.5 cm x 4.9 cm (50cm²)

- Weight: 2.8 kg (50cm²)

Operation Conditions:

- Operating Pressure: 0 - 50 psig

- Operating Temperature: 35 - 75 ºC

- Hydrogen production for 5cm2 : up to 35 SCCM

- Hydrogen production for 50cm2 : up to 350 SCCM

Lead time of 4 weeks to be expected.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.